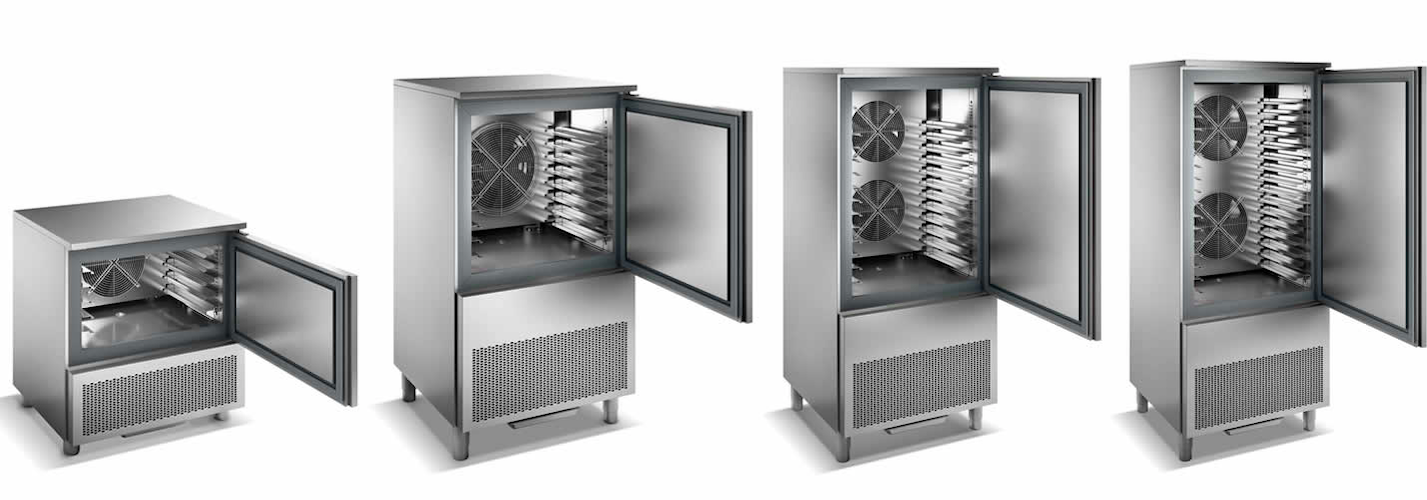

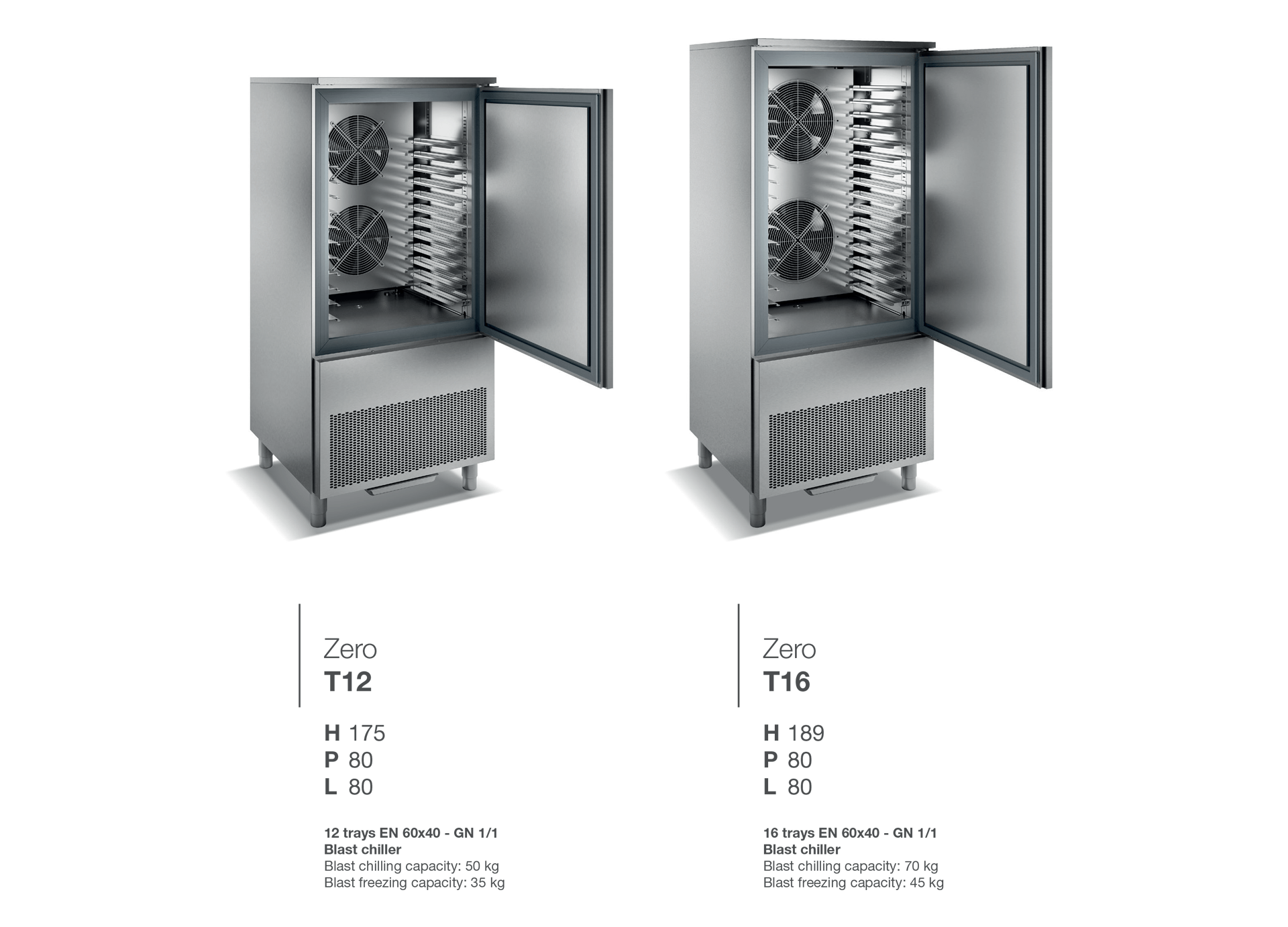

Zero

Are you interested in this product?

The Zero range of blast chillers has been designed to meet the demands of the commercial catering equipment, from bakeries to gelato and pastry shops, as well as the catering and food industry sectors. Zero blast chillers combine power and innovation with maximum environmental sustainability and energy saving. Ergonomics and minimal aesthetics linked to strict geometric lines that highlight the cleanliness and essentiality. Zero blast chiller, the perfect workmate.

Product range

Functions

Zero blast chillers are available in two different versions. Essential, with the essential blast chilling functions. Multifunction, is the All Inclusive version that allows you to exploit all the power of the 9 different functions and work programmes.

![]()

Blast Chilling +3°C

Blast chilling +3°C at the core of the product, from any starting temperature respecting the nutritional properties of each food.

Blast Freezing -18°C

Blast freezing down to -18°C at the core of the product, without damaging the structure and respecting the characteristics of the food.

Continuous Cycle

Positive temperature +3°C and negative temperature -18°C at the heart of the product, without time limits and without cycle interruptions by continuous insertion of food.

UV sanitizing

optional

UV lamps sanitize the inside of the blast chiller with a reduction of the bacterial load equal to 99.5%. allowing to use in speed and safety different production cycles.

UV sanitizing

optional

UV lamps sanitize the inside of the blast chiller with a reduction of the bacterial load equal to 99.5%. allowing to use in speed and safety different production cycles.

Proving

Complete management of natural proofing cycles with total control over temperature and humidity.

Slow cooking

Low temperature cooking of products with the possibility of combining positive or negative blast chill cycles.

Beverage cooler

Positive chilling cycles designed to quickly bring wines and other beverage to the ideal serving temperature.

Regeneration

Express preparation of meals at the desired moment. Food is kept at + 3 °C, and then regenerated at the selected heating temperature.

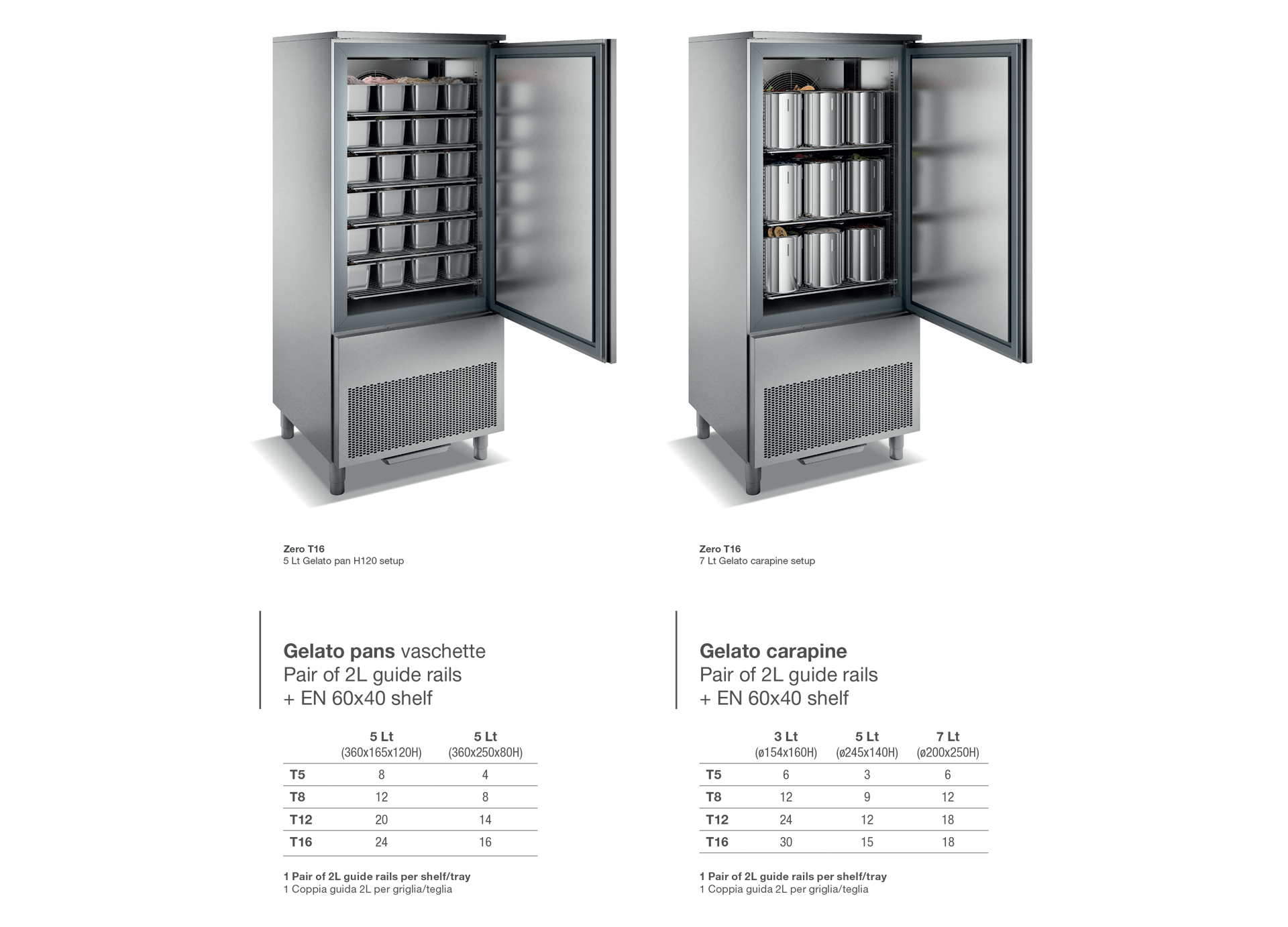

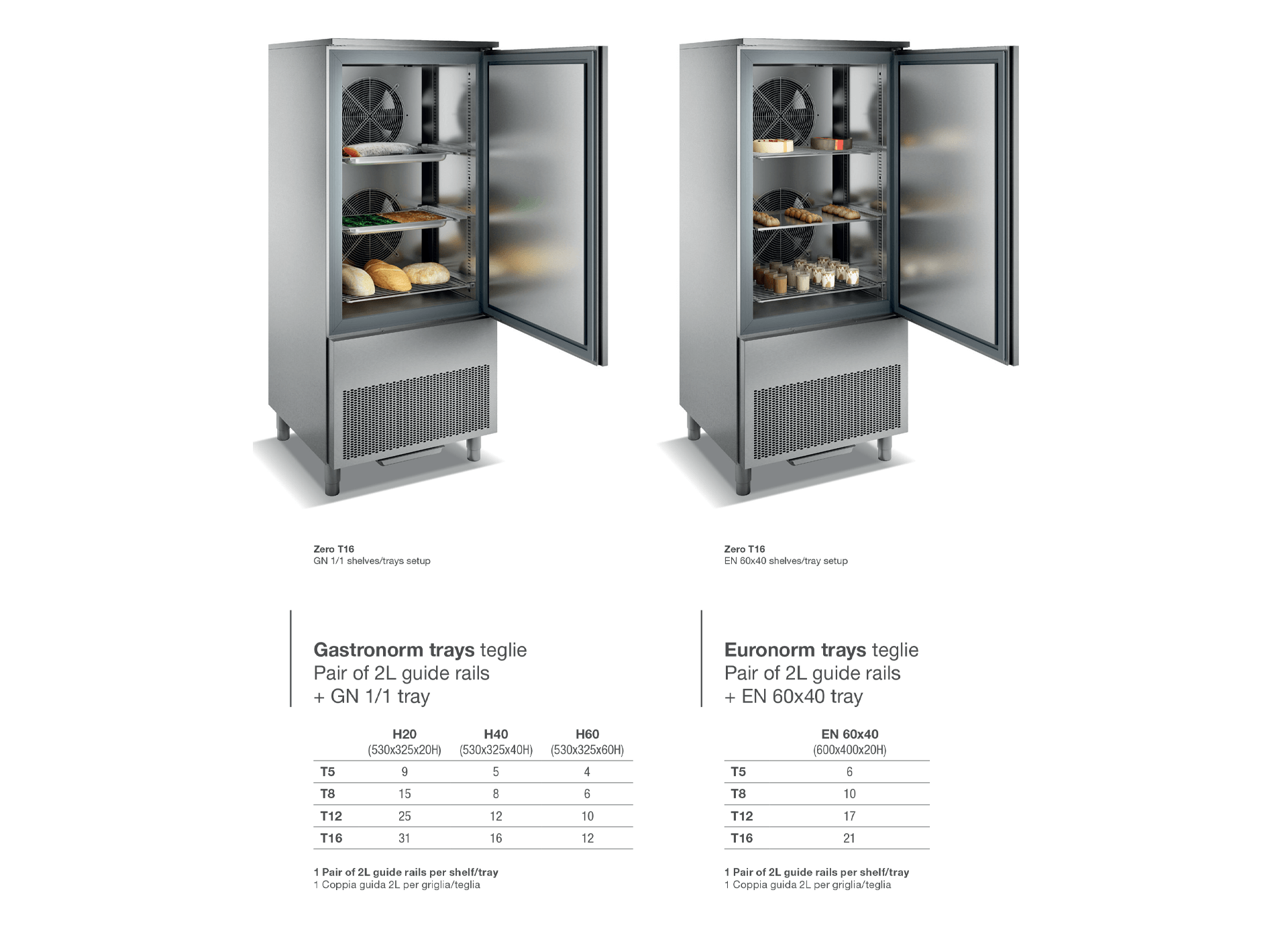

Internal Setup

Each blast chiller is equipped as standard with 4 stainless steel racks (15 mm pitch), a core probe (single point) and a pair of 2L EN-GN stainless steel guide rails (360 mm) with maximum load of 30 kg per shelf.

![]()

Natural technology and energy efficiency

Natural refrigerant

The entire range of blast chillers uses natural refrigerant R290, allowing the reduction of CO2 emissions emissions and the reduction of 5-10% of average energy consumption. The sustainable choice for the environment.

Cyclopentane natural insulation

The use of polyurethane foam with cyclopentane in addition to maximizing thermal insulation, allows the reduction of consumption and environmental impact. The thickness of insulation of the shells of 70 mm allows greater structural stability of the bench and a reduction in heat loss for further energy savings.

Electronic fans

The condensing unit and the evaporating unit are equipped with electronic fans with low noise and mechanical vibrations, allowing

a reduction of energy consumption up to 60%. L’unità condensatrice ed il gruppo evaporante sono dotati di ventilatori elettronici

a bassa rumorosità e vibrazioni meccaniche, consentono una riduzione del consumo energetico fino al 60%.

Low vibration

Free to work in maximum silence. The Lab blast chiller collection adopts the most advanced technologies to make the working environment silent and comfortable; the condensing unit is equipped with a hermetic compressor and electronic fans with low noise and mechanical vibrations.

Thermal break

The front structure of the compartment has a perimeter frame coupling the body of the blast chiller, with thermo- welded joint corners. Thanks to this it is possible to avoid thermal dispersion between the door gasket and the body, guaranteeing a high thermal cut between the inside and the outside of the blast chiller.

Ergonomics and maintance

Completely flat door

The perfectly flat door guarantees an effective grip and a perfect seal when closing. The 5-chamber gasket, in addition to being completely removable for cleaning, prevents the formation of condensation and allows a reduction in heat loss of about 10% compared to double-chamber gaskets.

Flexible door configuration

Blast chillers in the Lab range are arranged for left and right door installation. The configuration of the door opening direction can be selected when ordering from the configurator. Opening up to 170° with simultaneous locking in open position at 90°.

Finishing and internal surface flatness

Made of AISI 304 stainless steel, they are characterised by the flatness of the internal surfaces, which allows the optimisation of space and the reduction of turbulence in air circulation. The walls and bottom of the compartment are made with rounded corners, while the racks, flush with the internal walls, are completely removable.

Easy to clean

The interior design of the compartment is designed for maximum ease of cleaning: removable racks, rounded corners, removable gasket and flat interior surfaces.

In addition, there is a drain on the bottom of the basin (1 inch standard size).

Easy access to condensing unit and evaporator

Access to the condenser is via the practical removal of the front cover, without the need for special tools. Evaporator and fans are easily accessible through a closing cover, which can be opened like a door thanks to the hinge system.

Evaporator protective coating

A protective coating has been applied to the evaporator by means of cataphoresis, which eliminates the risk of possible refrigerant leaks due to corrosion phenomena resulting from the presence of citric acids and/or vinegar in certain types of preserved foods.

Performance

Heated core prove

The heated core probe supplied with the blast chillers measures the core temperature of the product, providing a precise measurement of the same and a perfect execution of the set programs.

Over 100 recepies

More than 100 pre-set operating cycles have been developed by a team of professional chefs, in collaboration with ISA R&D dept, to simplify and speed up the most common operations.

Create and safe custom cycle

Keeping every detail under control is the only way to make a difference. Zero blast chiller allows manual adjustment of all parameters, creating your own recipe book of customized production cycles.

Handling equipment

The stainless steel feet are height-adjustable (115-175H mm), ensuring stability of the blast chiller and aesthetic alignment between the modules placed side by side. Pivoting castors with directional locking brake are available as an optional to make moving the blast chiller as easy as possible.

Base with openings system

The compartment has been designed with a system of openings on the base that allow the disposal of heat even in cases of wall installation.

Display touch

The 7" touch display where the USB port is provided, is designed to be intuitive and easy to use for frequent use.

Technical features

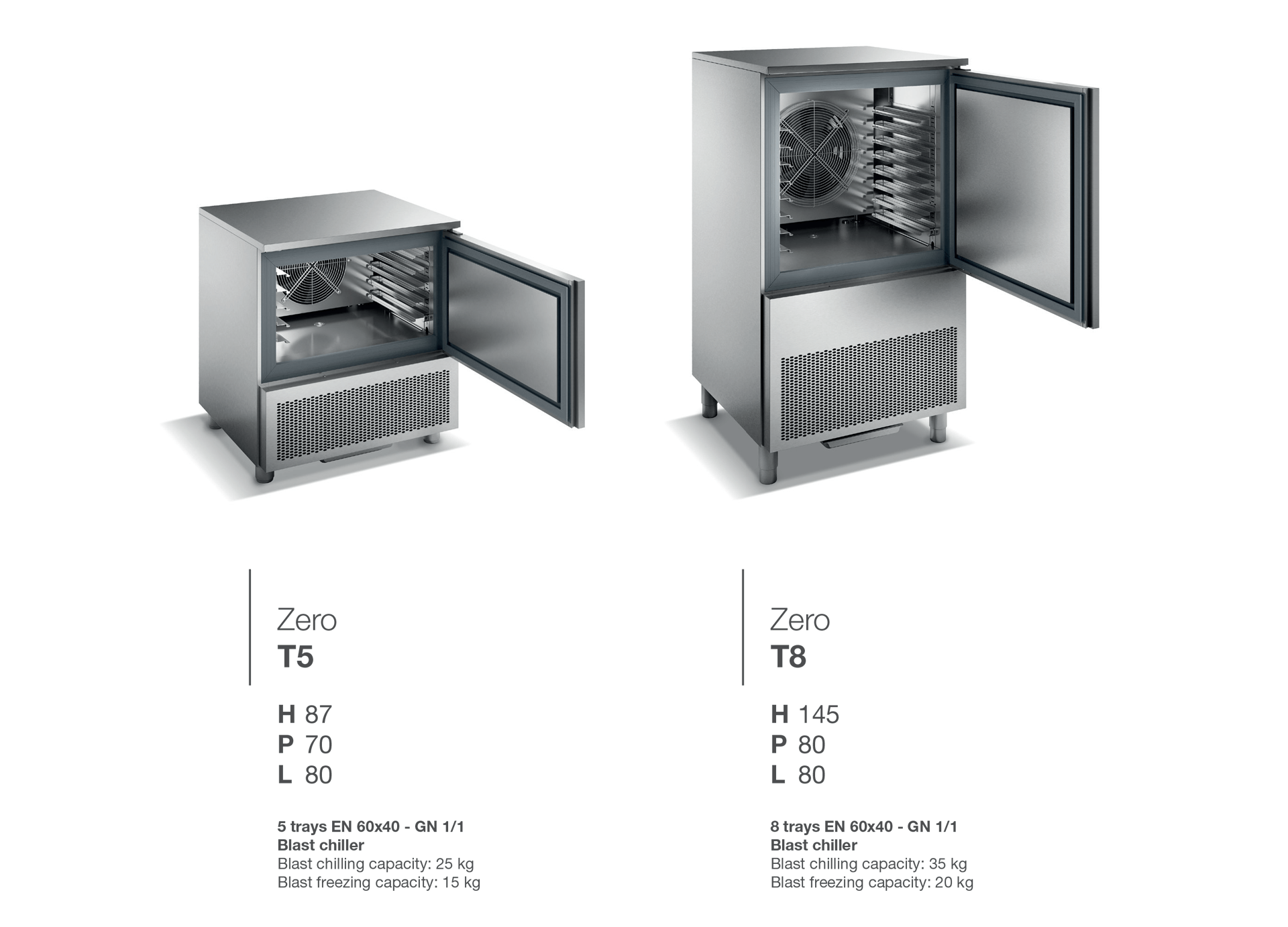

Zero

Installation

- Plug-in

Standard equipment

- T5: 5 pairs of guides 2L EN-GN stainless steel

- T8: 8 pairs of guides 2L EN-GN stainless steel

- T12: 12 pairs of guides 2L EN-GN stainless steel

- T16: 16 pairs of guides 2L EN-GN stainless steel

- 4 stainless steel racks pitch 15 mm

- Heated probe

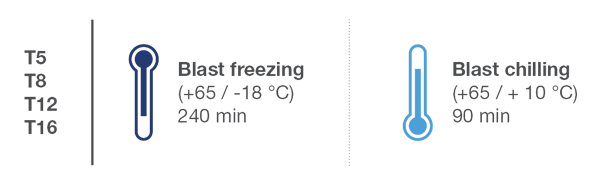

Ciclo abbattimento

- +65/+10 °C

Ciclo surgelamento

- +65/-18 °C

Refrigerant

- R290

Refrigeration

- Ventilated

Compressor

- Hermetic

Defrost

- Hot gas

Climate class

- 4 (30 C° / 55% RH)

Opening system

- Self-closing swing door

- Left or right configuration

Insulation

- Cyclopentane 70 mm

Base

- Height adjustable feet (115 - 175 mm)

- Swivel casters with brake (optional)

Inside color

- Stainless steel AISI 304

Outside color

- Stainless steel AISI 304

Optionals

- Swivel casters with brake

- Grid (400x600 mm) EN stainless steel

- Grid (530x325 mm) GN 1/1 stainless steel / plastified

- Pair guides 2L EN-GN stainless steel

- Tray (530x325x20/40/60H mm) GN 1/1 stainless steel

- Tray (400x600x20H mm) EN stainless steel